What's Coffee Processing?

- What does coffee processing actually mean?

- Washed Process Coffee

- Natural Process Coffee

- Honey Process Coffee

- Experimental Processing

- Other Coffee Processing Methods

- Anaerobic / Anoxiccoffee processing

- Carbonic Maceration Coffee Processing

- Extended or Controlled Fermentation Coffee Processing

- Thermal Shock Processing

- FAQ

What is coffee processing and why is it important in coffee production? Here we expand on each of the common methods in more detail.

What does coffee processing actually mean?

Put simply, coffee processing is the removal of the layers that surround the coffee bean (seed).

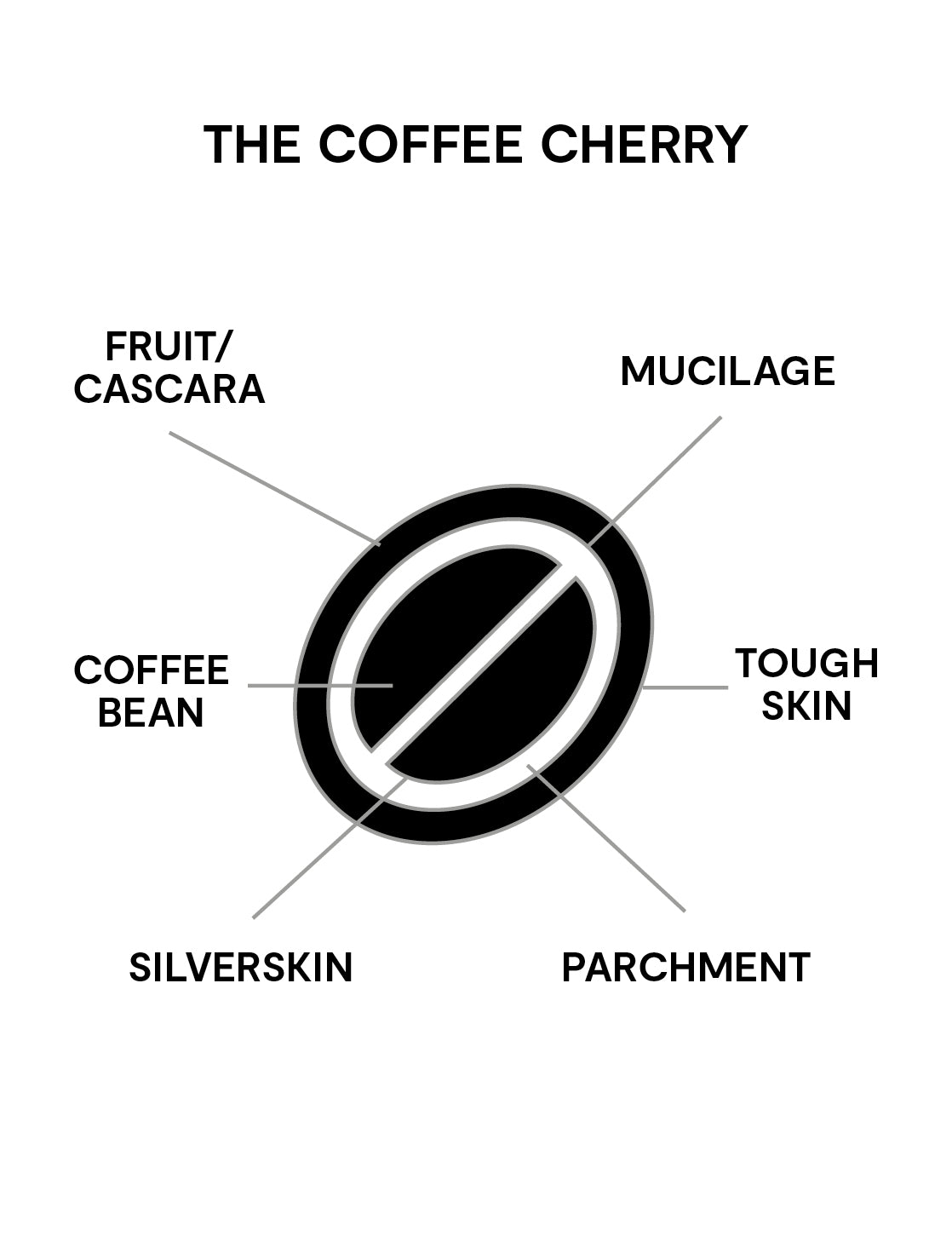

A coffee cherry is made up of several layers which include skin, fruit, mucilage and parchment. After the cherries are picked, they require processing which involves removing these layers. This can be done in a number of ways and each process can impart a different cup profile on the coffee.

Below are the three most popular ways of processing coffee, and the effects of each on the final cup.

Washed Process Coffee

The washed coffee process involves removing each layer of the coffee cherry before it’s dried. Whilst natural or honey processed coffees utilise the outer fruit to provide some flavour, washed coffees are almost totally reliant on the inner bean having gained enough carbohydrates and flavour during its growth. This means that environmental factors such as climate and terroir, coupled with operational factors such as fermentation and drying, are fundamental in showcasing the coffees true flavour.

To begin, harvested coffee is placed through a de-pulper to remove the skin and fruit. These machines can either be manual, which involve workers turning a wheel-mechanism to de-pulp the coffee, or they can be electric powered. Huge, industrialised machines can de-pulp coffee much quicker and more efficiently.

Inside these machines are carefully calculated disks (holes), which drive the coffee beans out of the fruit. As ripe coffee cherries are soft, when they pass through these machines they break and only the coffee seed (bean), passes through successfully. Unripe cherries are separated, often used elsewhere for natural processing or sold for lower prices to local markets.

The next stage is to remove the sweet, sticky mucilage that surrounds the coffee bean. This is done by submerging coffee in water, or placing in fermentation tanks for a certain period of time. Although typically between 12-36 hours, producers often experiment with different lengths of fermentation times to affect the profile of the coffee. After fermentation, the coffee is washed with clean water before being dried on patios, tables, raised beds or mechanical "parabolic" dryers. Washed process coffee is one of the most popular processes. Washed coffees often have a clean and crisp acidity, high clarity of flavour, with a low to medium body.

Washed Processing

Natural Process Coffee

Natural coffee processing is the world’s oldest and riskiest process.

Rather than removing the outer fruit as with washed processing, natural processing involves drying coffee cherries with the fruit and mucilage that surround the bean, left intact. This means that the natural sugars, sweetness and fruit flavours encased in the coffee cherry, begin to ferment and merge with the bean during drying.

Once picked and sorted for ripeness, the ripe cherries, in their full form, are taken to a drying area. It’s then placed on surface, usually a patio, table, raised bed or mechanical dryer – or a combination of techniques, and left to dry. The next stage must be carefully managed. What makes natural processing so challenging is not only the risk of uneven or over fermentation, where the fruit is left to dry for too long, but also of the development of moulds. These moulds at best diminish the coffee flavours and at most cause defective flavours or create a microbiological hazard for consumption. The coffee is turned frequently to avoid this, ensuring the maximum surface area is exposed to the air to facilitate an even drying. After an agreed amount of time when the coffee reaches a set moisture level, all of the outer layers of the dried cherry are removed in one step by a de-pulper or hulling machine.

This method tends to create a very bright, vibrant and intense cup, often with high sweetness and a heavy body.

Natural Processing

Honey Process Coffee

Honey coffee processing, or pulped natural coffee processing, are terms that are sometimes used interchangeably. The country of origin and producer traditions often dictate whether the coffee is described as a honey or pulped natural.

Broadly speaking, this is a process that sits in between washed and natural. These coffees are often fruit-forward, with a with medium sweetness and body and always a balanced level of consistency and clarity; showcasing both washed and natural processing cup attributes.

After the harvested coffee is pushed through a de-pulper, rather than placing the coffee in fermentation tanks like with washed processing, the coffee is moved directly to the drying area with the sticky mucilage left intact. Producers often experiment with leaving a different amount on the coffee to achieve different cup profiles and colour; each impacting the required length of the fermentation process. This relates to white, yellow, gold, black or red honey coffees that you might see on a coffee label.

Coffee Highlights

Experimental Processing

We are now seeing an increasing demand from consumers and cafés to showcase more unique approaches to processing coffee. These completely redefine what is possible, often showcasing an intriguing profile or flavour.

It’s becoming increasingly more common to see producers experiment with different washing or drying processing methods, and there is now more investment into farm level practices than ever before. Producers are exploring new technologies and expanding their research capabilities, even exploring the uses of acids and other ingredients in the fermentation stage of production: all in the pursuit of creating something special.

Other Coffee Processing Methods

Below are some alternate ways to process coffee that have gained popularity.

Anaerobic / Anoxiccoffee processing

The term “anaerobic” is a broad descriptor in the coffee world, used to describe a sealed, low-oxygen fermentation environment. “Anoxic” is a term that is becoming more commonly seen now, as it refers to the condition of the environment itself in which the fermentation takes place - capturing the essence of the difference of the process more accurately. Coffees processed in this way follow methods similar to that of a natural or washed coffee, with the difference that the fermentation tanks are sealed vessels, equipped with a one-way air valve that allows air out, but not in. The low oxygen levels limit the types of microbes that survive and engage in fermentation, giving the producers more control in the process, and a more constant end-result. Anaerobically processed coffee generally has a funky and complex flavour profile.

Carbonic Maceration Coffee Processing

In a carbonic method for coffee processing, coffee cherries are added to an airtight fermentation tank with a one-way valve, similarly to the anaerobic method. However, in carbonic maceration, the cherries are left intact, and the tank is injected with carbon dioxide. This process was originally used for wine production as an innovative way to ferment grapes without breaking their skins. The resulting carbon-dioxide rich environment causes a unique, internal fermentation reaction within the coffee cherry, opening new opportunities for producers to create new and complex flavour profiles, usually rich in dark red fruit notes.

Extended or Controlled Fermentation Coffee Processing

The pursuit of enhanced coffee quality and unique, more nuanced flavour profiles has led to increased experimentation with controlled or extended fermentation. Producers are now choosing different yeast strains based on the desired sensory profile for a specific coffee. Techniques such as intermittent washing and temperature regulation are also being employed to achieve these longer fermentation periods without introducing an undesirable taste. However, this method demands more careful management, as the risk of spoilage increases with fermentation time.

Experimental Processing

Thermal Shock Processing

Thermal shock coffee processing is a modern experimental approach, where coffee is exposed to dramatic temperature changes during processing. With endless opportunities for experimenting within the thermal shock method producing limitless results, producers can get creative. The theory behind exposing or interchanging the coffee to hot or cold conditions is to 'lock in' and optimise flavour and aroma compounds. The resulting coffee often has a bright and sweet profile.

FAQ

What happens to coffee after it's processed?

After processing the coffee cherries, the coffee beans undergo further steps before reaching your cup. Natural coffees are first depulped to remove the cherry. Then the next step for all coffee is careful drying to prevent mould growth and preserve quality. Next, coffee is sorted and graded, a meticulous process that separates them by size and density while also assessing it for quality and any potential defects. Finally, the papery parchment layer that still encases each bean is then removed through hulling before the coffee begins its journey to the roastery.

Where is coffee processed?

Most often, particularly in South and Central American countries, coffee is processed at farm level, beginning at a "wet mill", before being sent to a more central "dry mill" for final preparation before export.

How long does it take to process coffee?

Processing time varies considerably depending on several factors. Different methods involve distinct steps, resulting in timelines that can range from a few days to several weeks. Fermentation and drying times in particular are highly variable. Coffee can be fermented anywhere from a few hours to several days, while drying time is influenced by local humidity and temperature, and can also vary significantly.

What’s the best coffee process for espresso?

While coffee preferences are subjective, naturally processed coffees have become a favourite among baristas for espresso. Their sweeter, creamier profile, with fewer bright, astringent notes than washed coffees, makes them an ideal pairing for milk-based drinks like flat whites and lattes, resulting in a smooth and balanced cup.

What's the best coffee process flavour?

This ultimately comes down to personal taste. Different processing methods will shape a coffee's body, acidity, sweetness, and tasting notes differently – there is no better or worse, just personal preference. We recommend experimenting with differently processed coffees to find flavours that resonate with you.